High efficiency shrinking machine CCP-RS80

specifications

| Model | High efficient shrinking machine CCP-RS80 |

| Max packing size | 250*120mm |

| Conveyor speed | 0-7m/min |

| Supply voltage | AC220V/380V 6.5KW |

| Tunnel size | 750*370*180mm |

| Machine size | 800*700*1600mm |

Features

Application

standard shrink tunnel

specifications

| model | CCP-R525 |

| max packing size | 350*150mm |

| conveyor speed | 0-15m/min |

| Supply voltage | AC220V/380V 12KW |

| Tunnel size | 1500*450*250mm |

| Machine size | 1800*703*1310mm |

Features

Application

Vietnam PE heat shrink tunnel machine case story

In 2018, our company received a form of cable factory from Vietnam.The factory mainly makes cables.Their company requires that small coils of cable be packed with PE shrink film.And we need to seal them all.After the customer sent the photos of his products to our company.We analyzed and sorted out the scheme.PE shrink packing is a kind of heat shrink tunnel machine for cuff under normal conditions.The effect of cuff packing machine is that both sides of the product are not sealed.But not for the company’s cables.The customer asked that all cables be wrapped.So after communicating with the design, we confirmed the new schemeChoose L-type packaging machine, change the cutter to Pe cutter configuration, add PE search in the back section.The method of PE cutter and POF cutter is different.The POF sealing line is a thin line, so the POF cutter is a thin sealing line.PE is a kind of knife with air cut fuse mode.

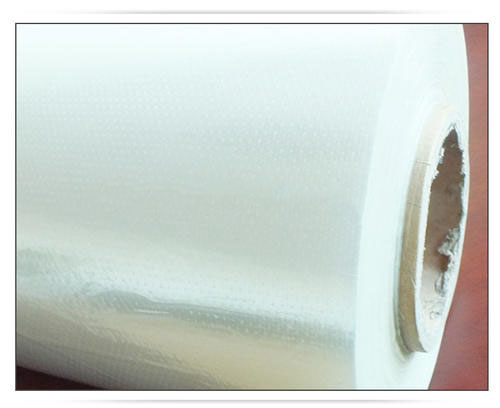

From the principle of heat shrink tunnel machine.PE full peak is the most important to solve the exhaust problem.How to solve the exhaust problem?The contraction principle of Pe shrinkage membrane is:After heating, the surface of the membrane material is baked soft,It is retracted after cooling.This search is complete.So there’s no way for the gas to escape from the tiny pinholes like TF.To get out of a big pinhole, or he needs to have a lot of holes.So in the process of debugging this PE compressor.The size of the air hole has a great impact on the exhaust effect, so some products after the search found that there is still a lot of gas is not eliminated, this is because there are not enough pores, or because the pores are not large enough.The radium perforated membrane is a way for me to punch all holes on the membrane material in the winding process after the completion of production. The size of the hole can also be customized according to the requirements.Next, I’d like to show you a sample of radium perforating membrane material.

Shrinkage machine for different membrane materials will have different design methods.There is heating and blowing, and the speed needs to be adjusted.These adjustable parts will help the contraction better.Well, if the blowing air volume is not adjustable, choose the one with the maximum air volume.In the selection of air motor, we generally choose 2800 RPM motor.The effect of high speed on shrink packaging is better.

After this customer in Vietnam, let us have a better understanding of the search packaging machine,PE.After receiving the heat shrink tunnel machine, the customer is very satisfied with the packaging effect.They also introduced us to their brother company.I believe that as long as you want to do it, you can do the machine well.Our experience tells us:To add a machine to do well, first of all, the principle of this machine should be very professional.Only very professional people can develop new fields.Machines and consumables are related, so the principle of consumables is also very professional.

L type packing machine +shrink tunnel for lunch box

side sealing packing machine for magazine+ shrink tunnel

L-type packing machine for sew thread+ R1500 shrink tunnel

L bar Packing machine + shrink tunnel

L sealer for steamed bread+ shrink tunnel

see more videos: